Battery Innovation at The Battery Show Asia: What’s Coming Next?

At The Battery Show Asia 2025, the energy industry convenes to ask a crucial question: What’s next for batteries? As demand skyrockets and the push for sustainable solutions intensifies, the pace of innovation has never been more critical.

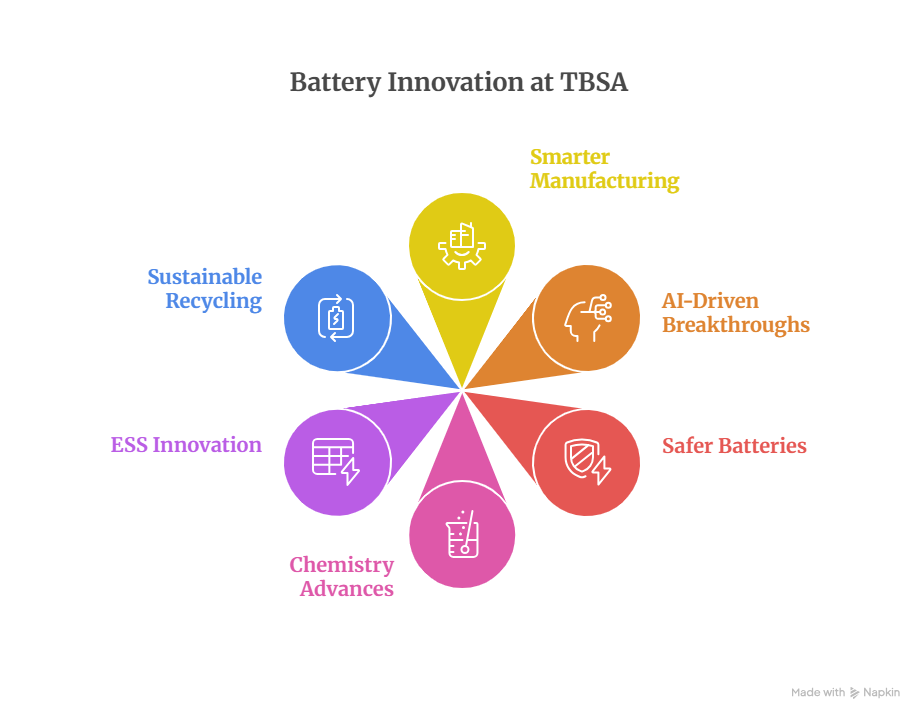

This article explains the six TBSA Tech Tracks that highlight where battery innovation is moving and what you can expect from the industry moving forward; keep reading!

Smarter Battery Manufacturing: From Pilot Lines to Scalable Perfection

The industry is making progress in defect-resistant pack production, inline electrode measurement, and ultrasonic quality control, all designed to cut errors and boost efficiency at scale.

Real-time monitoring systems are now central to production, with AI-driven automation that adjusts processes instantly to keep consistency. Virtual cell behavior modeling is also becoming an important tool, allowing engineers to predict performance before products leave the factory.

In the past, quality control relied on end-of-line inspections to catch problems after they appeared. That method is no longer enough for today’s complex and high-volume production. Now, quality assurance is being built into every step of the process, shifting from a reactive to a proactive approach.

AI-Driven Breakthroughs: Accelerating R&D and Predictive Production

At The Battery Show Asia 2025, AI took center stage with deep learning models that detect faults early, predict long-term performance, and provide clearer insights into battery health.

AI is also reshaping R&D. Algorithms now test thousands of material combinations far faster than traditional trial-and-error, speeding up new chemistry development. In inspection, AI systems catch defects missed by human checks, raising overall production quality.

On the factory floor, AI-enhanced laser welding and automation tools adjust in real time to maintain weld precision, reduce variation, and lower costs—delivering more consistent production at scale.

Safer Batteries by Design: Total Lifecycle Safety Architecture

Safety remains one of the most important topics in battery innovation.

Smart software platforms are being developed to monitor thermal conditions inside EV batteries in real time. By flagging potential hazards before they escalate, these systems give manufacturers and operators an additional layer of protection that directly reduces the risk of fire-related incidents.

Hardware innovations were also highlighted, including redesigned venting units, improved pyrotechnic devices, and new fire mitigation strategies to contain damage from cell failures.

The discussion around safety is no longer confined to the vehicle or the module. At TBSA 2025, lifecycle safety management was presented as a holistic framework that begins with material selection, continues through cell and pack design, and extends to deployment in battery energy storage systems.

New Chemistry, Solid-State, and Commercial-Ready Advances

Presentations at TBSA 2025 highlighted advances in solid-state electrolytes aimed at reducing thermal runaway and improving battery stability.

Modular systems designed for commercial fleets were also introduced. They allow operators to adjust capacity to meet different route or load requirements, combining flexibility with easier maintenance.

Roadmaps shared at the event detailed progress toward all-solid-state lithium metal cells and other advanced chemistries. While technical challenges remain in the new battery technology, the timelines suggest that several of these technologies could move from pilot-scale projects to practical deployment within the coming decade.

Energy Storage System (ESS) Innovation: Safer, Cheaper, Longer

Long-duration storage was a recurring theme, with sulfur-based flow batteries attracting particular attention. Their low-cost chemistry and potential for extended discharge times make them promising solutions for supporting renewable-heavy grids.

Artificial intelligence is also accelerating progress in grid-scale storage. AI-enhanced discovery tools are identifying new materials that can deliver safer and more efficient ESS solutions at lower cost. This approach shortens development cycles and speeds up the path to deployment.

Closing the Loop: Smarter, Sustainable Battery Recycling

Sustainability was a central theme at TBSA 2025, with recycling positioned as a key element of supply chain strategy. New approaches focused on cutting emissions during collection, processing, and reuse, highlighting how recycling contributes directly to decarbonization goals.

Direct recycling methods were also in focus. These approaches recover valuable materials like cathodes and electrolytes without breaking them down completely, saving energy and reducing chemical waste.

New recycling methods are shifting away from harmful solvents and chemicals. Water-based systems and PFAS-free processes were highlighted at TBSA 2025 as safer, cleaner alternatives that still deliver strong recovery rates.

Wrapping-Up

The Battery Show Asia 2025 demonstrated how innovation across manufacturing, AI, safety, chemistry, energy storage, and recycling is reshaping the industry. Whether the global battery ecosystem is fully ready for the scale of transformation ahead is still uncertain, but the direction is clear.

Register now to attend The Battery Show Asia 2026, which will continue the conversation and provide another chance to see how the sector is moving forward!